Maintaining a high level of factory and industrial cleaning in Australia often presents unique challenges compared to other commercial locations. Factories often contain heavy machinery, expansive floor spaces, and hard-to-reach areas that can accumulate dust, grease, and other hazardous materials. For industries like food manufacturing or hardware production, cleanliness is not just about appearance; it’s a critical element of meeting strict health and safety standards. This is where specialised factory cleaning services become a must.

At SCS Group, we understand these specific needs and offer tailored factory cleaning solutions designed to address these challenges. For example, in food manufacturing environments, we use specialised, non-toxic cleaning agents and techniques that effectively sanitise equipment and surfaces without leaving harmful residues. Our team of professionals are trained to handle the complexities of factory environments, ensuring that every area, from machinery to high-reach spaces, is thoroughly cleaned to maintain a safe and efficient workspace.

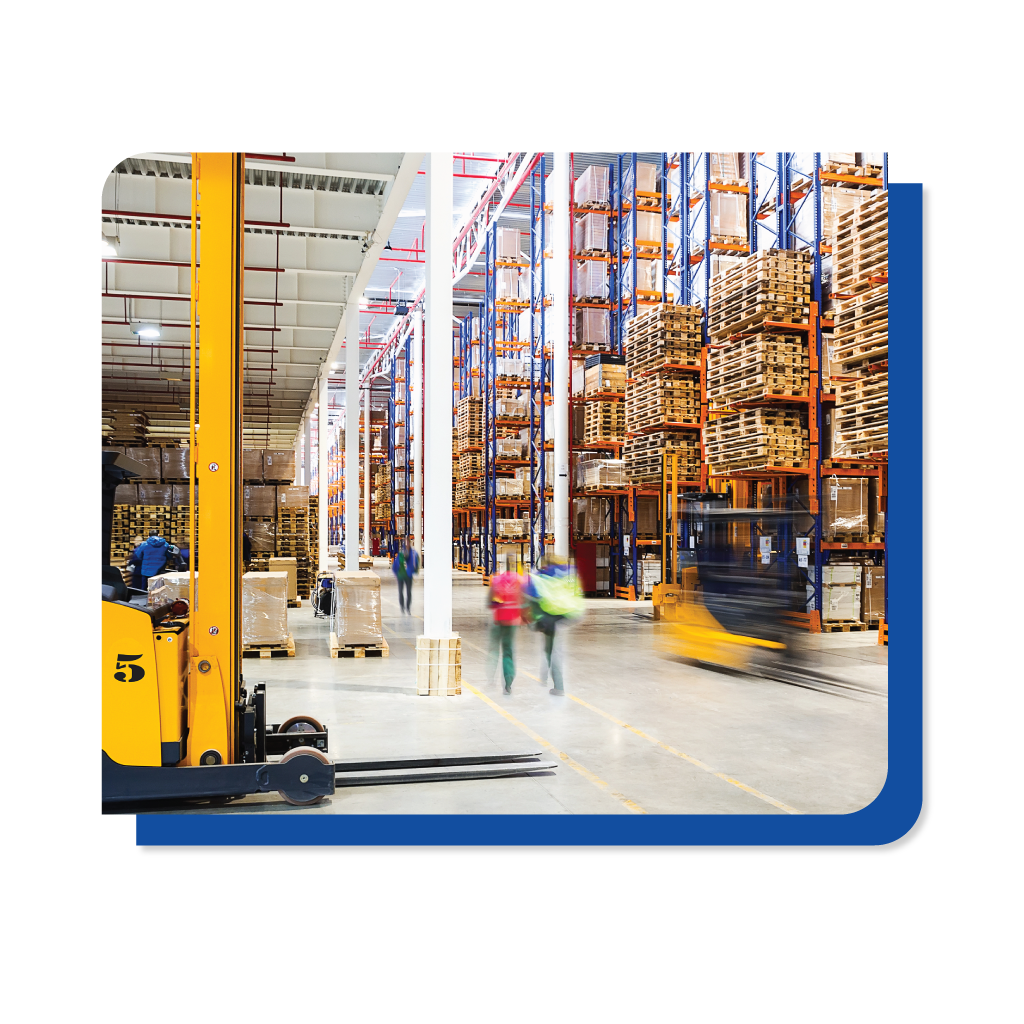

Professional Commercial Factory Cleaning

To maintain a clean, safe, and efficient factory environment, it’s important to address the specific cleaning needs of various areas within the facility. Different parts of a factory require specific cleaning approaches to ensure they remain free from dust, grime, and other contaminants. Here are some essential factory cleaning services every business should consider to keep their operations running smoothly and safely:

- Industrial Floor Cleaning: Essential for removing grime, oils, and debris from factory floors to prevent slips and ensure a safe working environment.

- Equipment and Machinery Cleaning: Involves removing dust, grease, and buildup from machinery to maintain efficiency and prevent breakdowns.

- High-Reach Cleaning: Targets dust and debris in hard-to-reach areas, such as ceilings and beams, improving air quality and safety.

- Concrete Pressure Washing: Used for deep cleaning of concrete floors and surfaces, removing stains and dirt buildup.

- Warehouse Cleaning: Keeps storage areas clean and organised, ensuring goods are stored in optimal conditions and minimising safety hazards.

Proven Expertise and Client Satisfaction

SCS Group is committed to providing quality services and client satisfaction. These promises are demonstrated through our customer retention rate of 98.5%. With over a decade of experience working with companies like TTI, we are dedicated to delivering top-quality factory cleaning services that adhere to the highest standards of safety and efficiency. Our comprehensive policies and procedures cover every aspect of the cleaning process, including:

- Workplace Health and Safety Training: Induction programs, risk control, hazard identification, and environmental safety.

- Security and Emergency Protocols: Robust procedures for security and cleaning emergencies.

- Specialised Cleaning Techniques: Biohazard cleaning, forensic cleaning, and site-specific surface training.

- Equipment and Chemical Handling: Safe practices for manual handling, equipment use, and waste management.

- Assessment and Compliance: Regular competency assessments and strict adherence to PPE requirements.

These protocols ensure that we provide reliable, safe, and effective cleaning solutions tailored to the unique needs of each factory environment.